4 Simple Techniques For Sheroz Earthworks

4 Simple Techniques For Sheroz Earthworks

Blog Article

Sheroz Earthworks Fundamentals Explained

Table of ContentsSheroz Earthworks Fundamentals ExplainedThings about Sheroz EarthworksGetting The Sheroz Earthworks To WorkThe smart Trick of Sheroz Earthworks That Nobody is Talking AboutThe smart Trick of Sheroz Earthworks That Nobody is Discussing

For any earthwork contractor, it is essential to perform deal with high quality, accuracy, and on timetable. Using equipment control in job machines allows optimizing the different stages in the earthwork process, from intending to the maintenance stage - trimble tripod parts. The machine control system aids the machine operator in achieving the target aircraft quickly and quickly

The maker control system overviews the operator with centimeter accuracy. With Xsite PRO 3D, you'll constantly know exactly just how much to reduce or load. Your local Xsite technological support can assist you and assist with any type of issues without visiting the website. Remote assistance saves money and time, as it reduces downtime in jobsites.

Unknown Facts About Sheroz Earthworks

Our system's components are very carefully developed to endure the rough problems of construction websites. Contrast of the exact same task executed utilizing equipment control versus the standard method discloses that, on standard, the typical method needs 50% more time to complete the same task as the technology-assisted method.

Seems great? Get in the Xsite equipment control system; it's below to supply you with a substantial benefit when dealing with earthmoving equipment. Discover just how Xsite Device Control can enhance your productivity and make certain job security! We understand that finding out a new modern technology may feel like a drag, however don't fret! Our pleasant and specialist local assistance solutions have actually obtained you covered, ensuring that you can keep working smarter without interruptions while on the task! Through remote support, your local Xsite dealership can provide advice or troubleshooting without having to go to the website! What type of excavators does maker control fit? Xsite Device Control systems can be mounted to any type of excavator from mini excavators to huge mining excavators.

Just how does equipment control job? In 2D systems, the machine is geared up with adjusted disposition sensors.

The system is very easy to learn the fundamentals can be educated in under one hour of training. Just Click This Link how does the remote support work? A wireless internet connection makes it feasible to establish a remote connection between the machine control system and the solution.

Some Known Details About Sheroz Earthworks

What sort of information layouts Xsite systems support? Xsite Device Control systems support open common file formats, enabling seamless info flow from one system to another. Supported file formats: 2D-Maps: DXF Point files: DXF, XML, GT, CSV, KOF, PXY Geometry lines: VGP, SBG, XML, Anpakke Surface Models: DXF, XML What elements are set up on my equipment? Depending on your choice of system (with or without positioning, i.e - fj dynamics autosteer review., 2D or 3D), your equipment is equipped with disposition sensors, a controller system, and a display/operating panel.

Lots of software and hardware options exist to help figure out a device's existing position on the earth and compare it with a preferred design surfaceand construction operators can do even more to take advantage of the benefits. Maker control is making use of various positioning sensors and a display screen to offer the driver with a recommendation in between the placement of the bucket or blade and the target quality.

Depending upon the arrangement, maker control systems can provide the driver with an easy aesthetic guide to bucket or blade placement, or can automatically relocate the blade to quality by chatting to the equipment's hydraulics - https://www.reddit.com/user/sherozau/. There are equipment control systems available for almost any type of equipment: , dozers, excavators, dirt and asphalt compactors, scrapes, leaners, milling devices, and pavers

What Does Sheroz Earthworks Do?

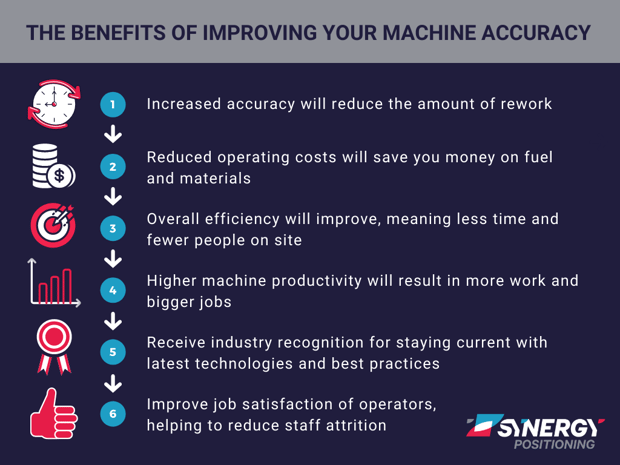

Some benefits consist of lowered rework, boosted task efficiency, and reduced surveying costs. Equipment control can additionally assist increase productivity and reduce overall costs. This innovation is transforming the method the building and construction sector functions. Building and construction devices without equipment control will end up being a distant memory and the advantages got from it will be various.

Trimble machine control systems supply a myriad of advantages to any person who utilizes earthwork equipment and, at EarthCalc, we can provide you with 3D data for your maker control-enable tools. Not exactly sure if maker control deserves the expense? Think about the complying with reasons that you need to consider this choice.

Utilizing GPS aligned with your 3D style documents, these systems practically guarantee that you will remove or put the appropriate amount of product at the building and construction site. On the majority of construction sites, remodel is a common and frustrating fact, however with Trimble machine control, you can remove the requirement for rework.

Sheroz Earthworks Can Be Fun For Everyone

Typically, with Trimble machine control, you can remove excess equipment at a specific work site. A work that may have needed the usage of 3 or four pieces of digging deep into devices currently could require only two pieces of equipment to achieve the same task in less time. This allows you to relocate your equipment to one more work website and handle numerous tasks at one time.

Report this page